Manufacturing Fixture in Automotive Interiors

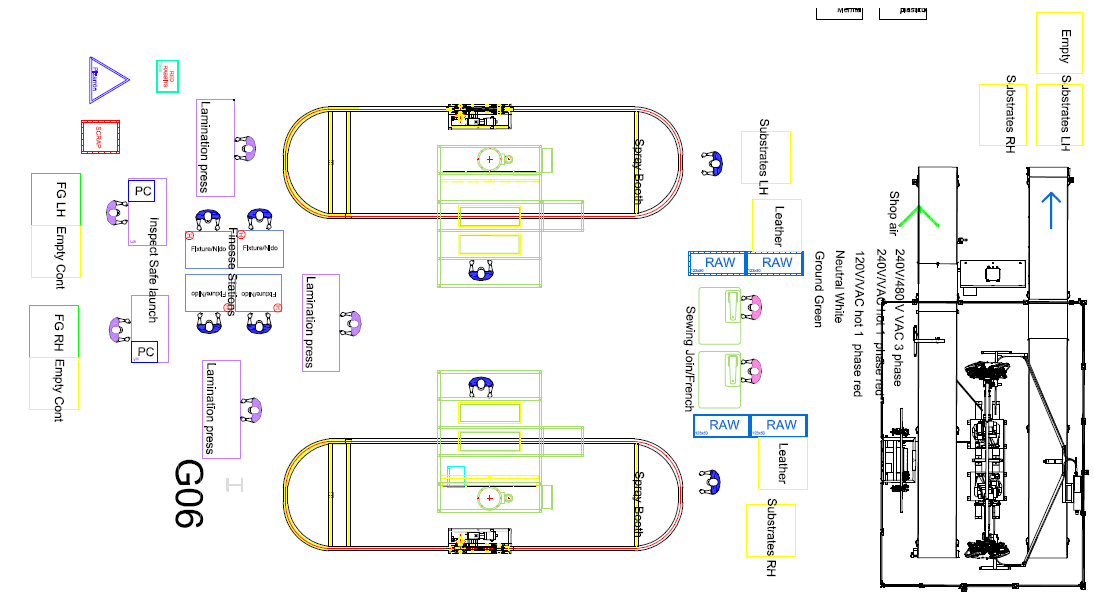

Cut, Sew and Wrap Production Line for BMW

Local Tier 1 supplier, Yanfeng (formerly known as JCI and Prince Corp.) brought on a Broadview manufacturing engineer to develop a partially automated cut, sew and wrap production line for BMW center consoles. In addition to designing much of the process from scratch and keeping the project on track, we were able to speed up the design process with overnight 3D printed prototypes.

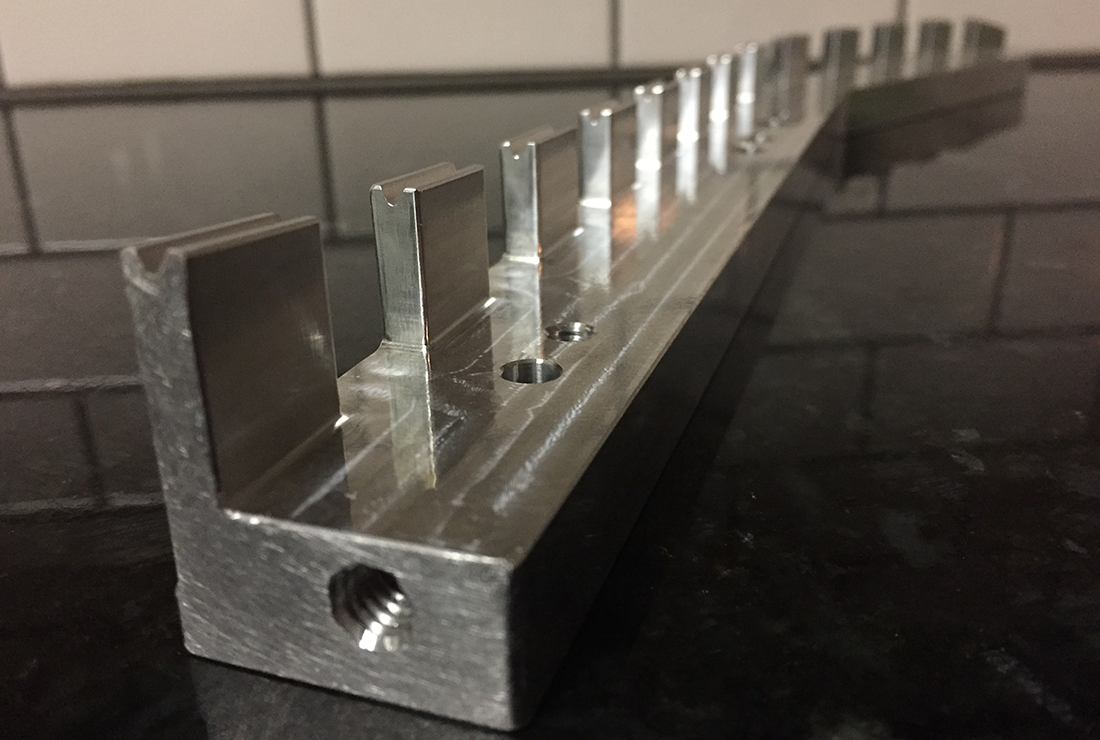

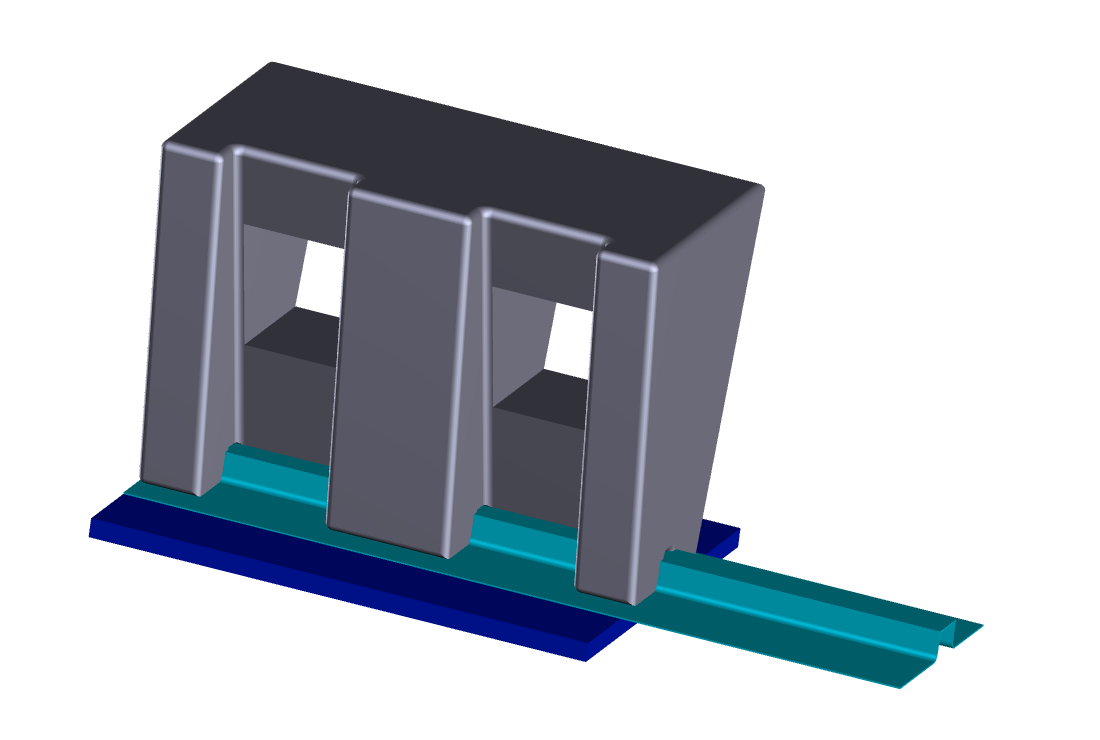

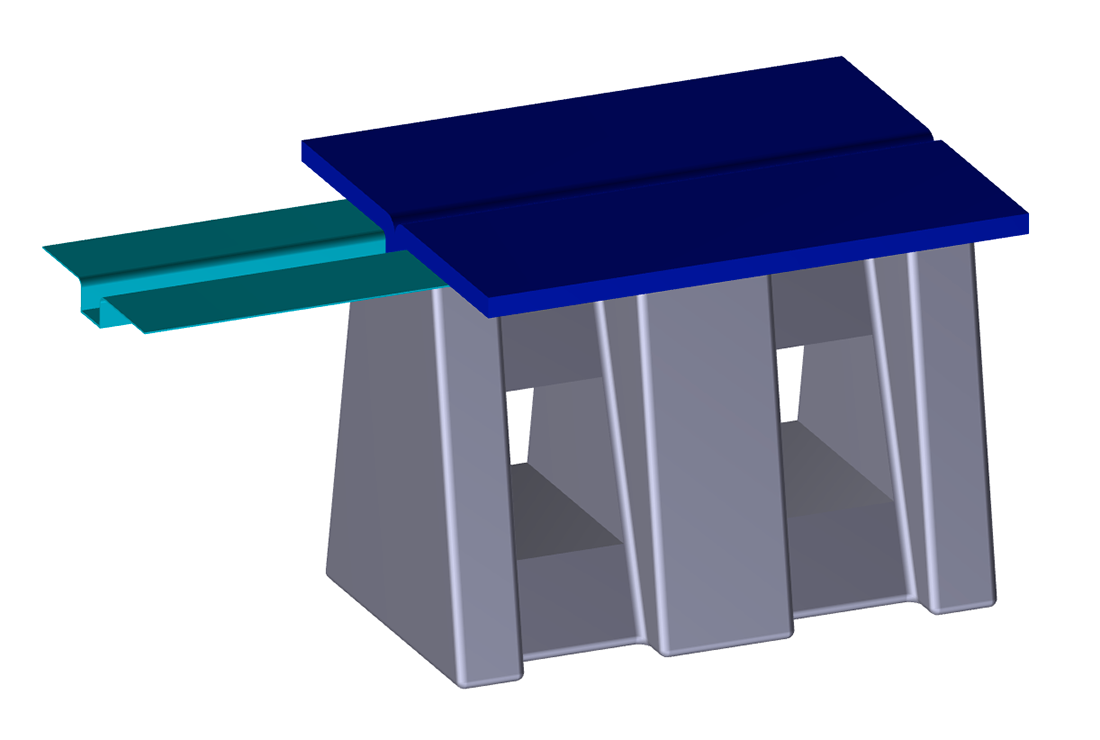

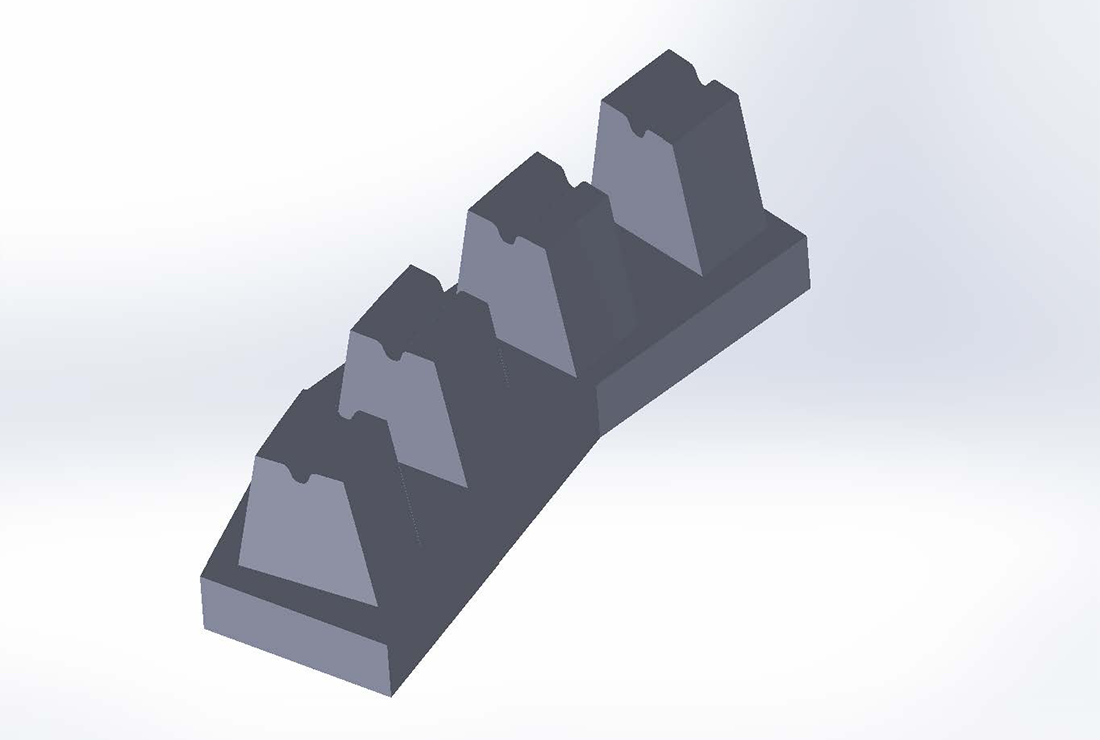

Our engineer designed a fixture that would align the seams of the leather against the edge of the plastic center console during the gluing process. Using one of our 3D printers, he built a small sample of the fixture overnight to demonstrate its function to his customer, and got approval to have the larger aluminum version made that same day, keeping the project on schedule.