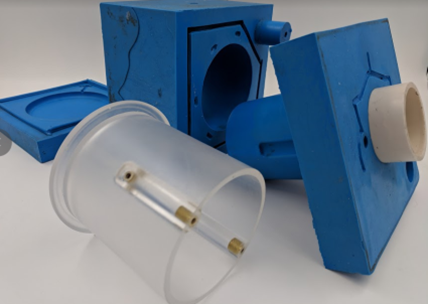

Cast Urethane parts using RTV Molding

Silicone Urethane casting, also known as room tempurature vulcanization (RTV), silicone molding or resin casting.

Many production plastic materials can be simulated through the use of RTV Molding. Urethane cast parts are ideal for low quantity production when volumes do not justify investment in injection mold tooling as well as for first run production parts. Urethane cast parts are also commonly used when your new start up venture cannot accurately predict production volumes, which allows you to keep initial investments low.

Finishing options

- Clear, Opaque, Custom Colors

- Painted

- Sand and/or Blasting to any level

- Applied Textures, Stipples

- Polishing from Matte to High Gloss

- Lenses, Polished, Clear-Coat

Broadview Product Development can provide YOUR team with prototype and start-up volumes in quantities from 10 to 1000 that look, feel, and perform like production injection molded parts. Urethane casting can be lower cost and higher quality than 3D-printing alone, and with low cost tooling and parts in as little as 3-5 days.

CNC Machining

CNC Machining services for YOUR low volume production. Typical quantities are in the range of 10-1000 pieces per year. CNC machined parts are ideal when your new start up venture cannot accuratley predict production volumes, which allows you to keep initial investments low.

MATERIALS

- Aluminum Alloys (6061, 7075 and many more)

- Steel Alloys

- Stainless Steel

- Non-Ferrous Metals (Copper, Brass etc.)

- Plastics (PVC, Delrin, Acrylic, Polycarb, UHMW, Nylon)

- Phenolics

FINISHING OPTIONS

- Media Blasting/Sand Blasting/Tumbling

- Polishing

- Painting

- Anodized

- Plating

- Heat Treatment

- And Others

We provide low volume production machining services to create aluminum and plastic parts from 10-1000 pieces per year along with extrusion value-add machining such as high tolerance cutting, holes, taps, miters, etc.

We will 3D-Print YOUR design, and our engineers can provide design services for you when needed. With our fast turn-around quality 3D-printing combined with our finishing capabilities we will create the parts you need on-time, and on-budget.

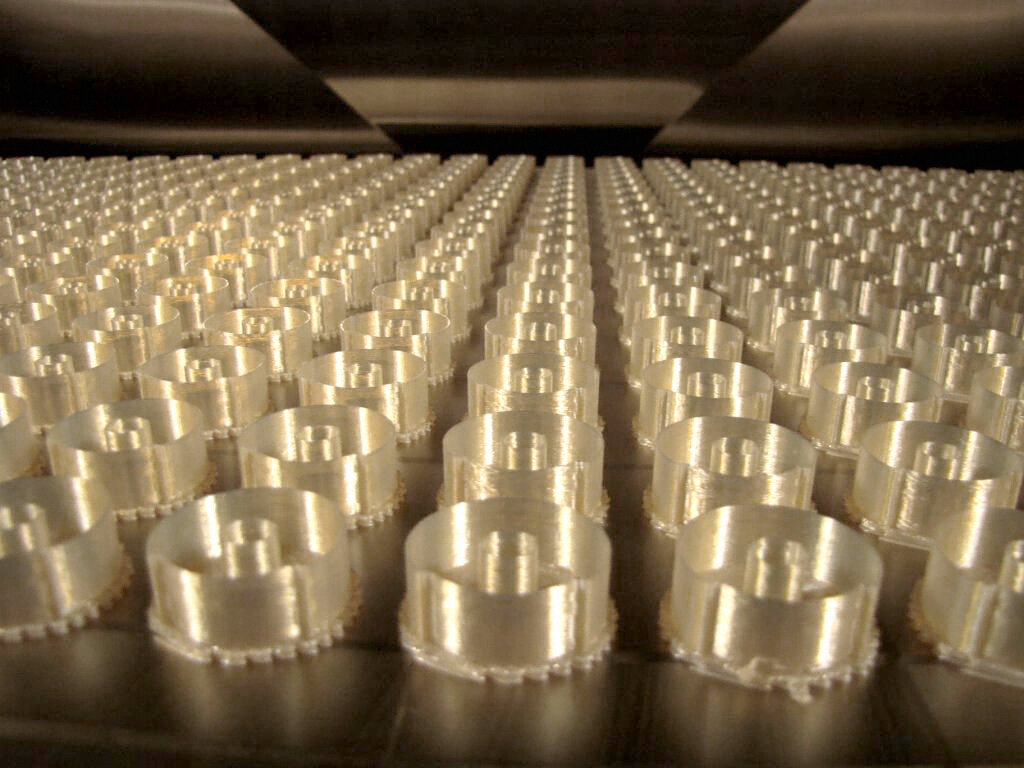

3D Printing

Broadview Utilizes Commercial 3D printers to produce quality parts within your timeline.

low volume production material options

- ABS M30

- PC

- Nylon 12(Black)

- ASA (many colors avalable, UV stable)

- PC-ABS (black)

- ULTEM 9085 (heat and chemical resistant)

available finishing options

- Sand and/or Blasting to any level

- Chroming or Metalizing

- Paint, Textures, Stipple