Rapid Plastic Prototypes

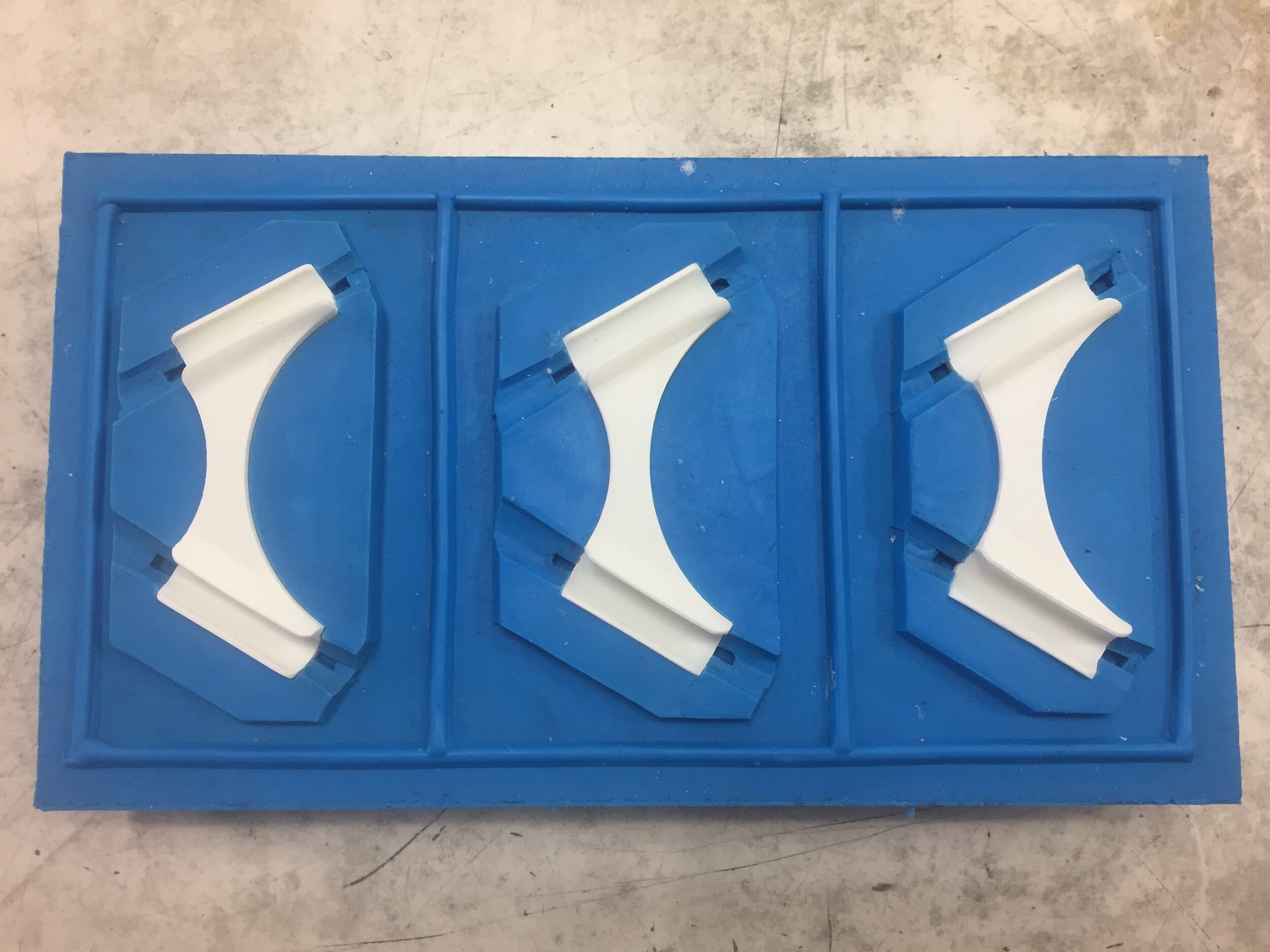

Urethane casting is a manufacturing process used between prototypes and high volume production.

Many production plastic materials can be simulated through Silicone Urethane Casting (RTV) from elastomeric rubber to hard injection molded plastics, from water clear to tinted to opaque, even color matched, or glass fiber fillers for additional strength when needed.

Urethane casting can be lower cost and higher quality than 3D-printing alone with affordable tooling and first parts in as little as 3-5 days.

How the Process Works

Urethane Casting (RTV Molding)

Do you need production representative prototypes but are not ready to invest a substantial amount in tooling?

Ideal for quantities from 10 to 100 that look, feel, and perform like production injection molded parts.

Rapid Tooling

First parts are often available in as little as 3-5 days for sample approval. Using a silicone mold allows our craftsman to prepare the first parts much quicker than most plastic injection molding processes while still yielding a show ready surface finish and keeping to your tolerance specifications.

Urethane Casting is a great alternative to injection molding when low quantities and short lead times are needed.

Redefining the Rules of Plastic Molding

Urethane casting provides many unique solutions for production in comparison to plastic injection molding. One of the most notable characteristic is the ability to cast parts without draft, as well as overcoming undercuts due to the flexibility of the tool. In addition, threaded inserts, over-molding and a wide variety of durometers to glass fill are just some of the benefits of choosing urethane casting for your prototype or low volume production needs. Contact us today to learn more about our manufacturing capabilities and how we can help you.

From threaded inserts to glass-fill, Urethane Casting can be a great option for many applications.

Years of EXPERIENCE

30 years of client trust in Broadview Product Development with projects large or small, corporate projects or individual inventors, concept development or product launch through production.

Finishing

See our extensive list of finishing options for Your show ready and functional prototypes.

Engineering

Our Integrated Team of Engineers and Model Makers work together to bring you high quality parts to your specifications.