What Is FDM?

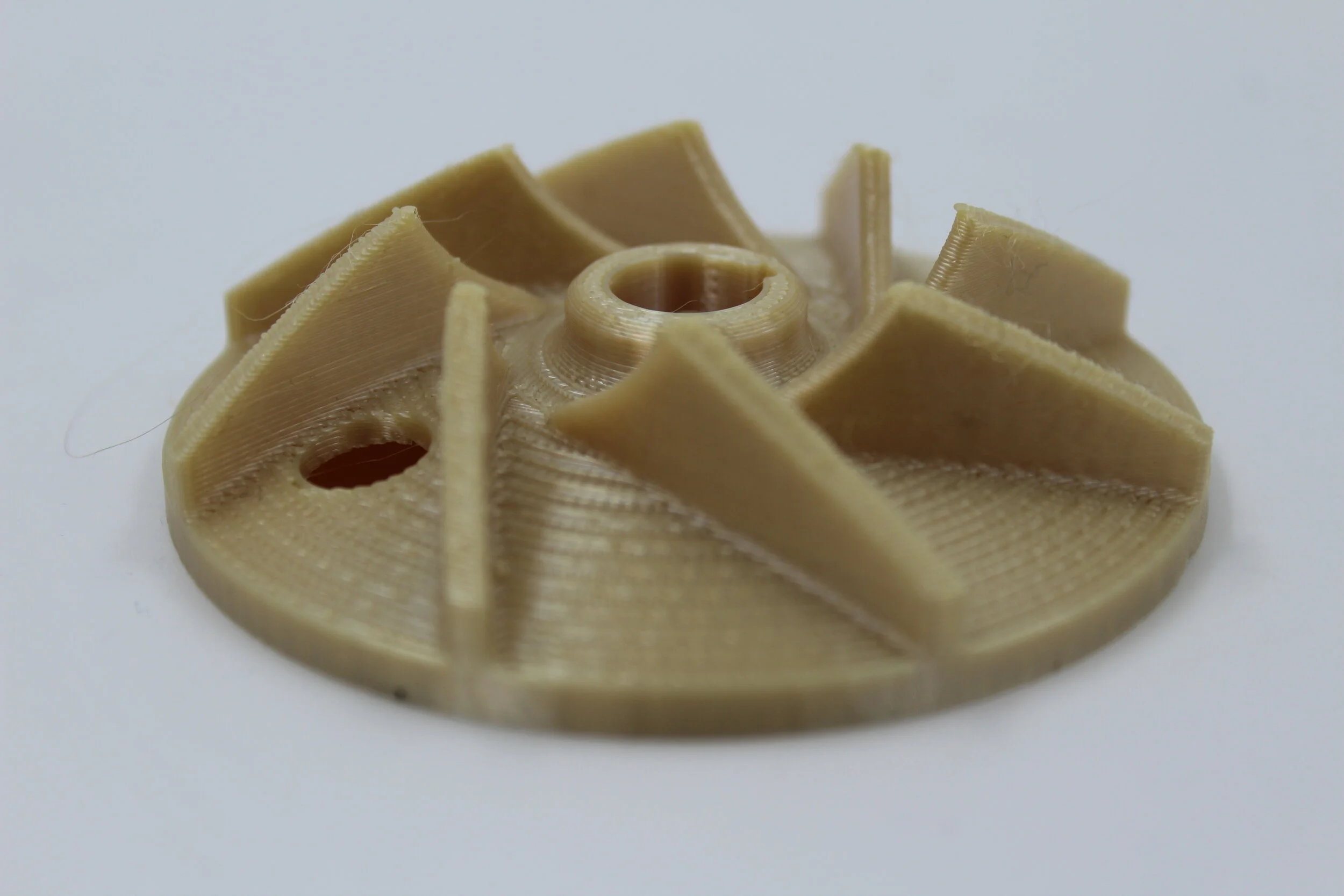

Fused deposition modeling

3D printers that run on FDM Technology build parts layer-by-layer from the bottom up by heating and extruding thermoplastic filaments.

Materials and Material Data Sheets

ABS M30

Nylon 12 Black

A great option for 3D printing, very versatile with great detail and performance. Nylon 12 Black Material data steet.

Polycarbonate

Ultem 1010 and Ultem 9085

Tough, Durable, Heat resistant material that is designed to endure the most rigorous conditions. Ultem 1010 and Ultem 9085 Data Sheets

Flexible TPU 95 Shore A

Typical Uses

Prototyping

Test custom parts with the same material as your production injection molded parts

Concept Models

Allows Product Designers a physical representation of their product through the iterative process.

Tooling

Jigs & Fixtures for Manufacturing floor

Production Parts

Low volume production and custom parts

Properties

Specialty Materials

Including options for flexible or high strength Materials.

Composites & High Temperature

Heat deflection temperatures up to over 215˚C (419°F) offering exceptional performance under extreme conditions.

Typical 3D-Printing Finishing Options

Standard Finish

Standard 3D Printing finish (as printed)

Supports removed, light sanding to 220 of support faces and/or bead blast.

Mold Ready

Remove supports, remove all exterior surface build lines

Sand to 320 and/or bead blast

Painted

Remove supports and layer lines on visible surfaces (A-surfaces)

Sand to 320 and/or bead blast entire part.

Paint

Engineering Clear

Remove supports, sand to 320 and/or bead blast,

Remove all exterior build lines

Apply clear coat

Custom Finishes

Let us know what you need!